Sandwich panel

Sandwich Panel

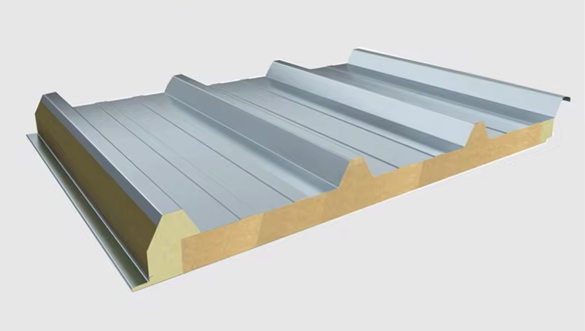

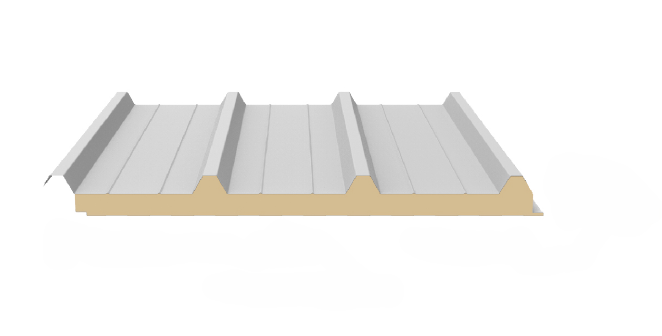

Sandwich panel, also known as composite panels or structural insulated panel, is a type of multi-layer structural cladding system that consists of two thin and strong metal sheets attached to a substantiating core material. The metal sheets are coated with a corrosion-resistant coating and the core material is usually polystyrene, polyurethane, mineral wool.

In building and construction, these prefabricated products designed for use as building envelopes. They appear in industrial and office buildings, in clean and cold rooms and also in private houses, whether renovation or new-build. They combine a high-quality product with high flexibility regarding design. They generally have a good energy-efficiency and sustainability.

Sandwich panels for construction

Sandwich panels are a universal building material, of high quality fire resistance and very good thermal insulation. They allow you to shorten the construction time, reduce costs and create visually interesting objects. Sandwich panels work well during the construction of industrial, commercial, logistic and warehouse facilities, and in recent years they have also been used to build single-family houses. We invite you to familiarize yourself with our wide range of sandwich panels.

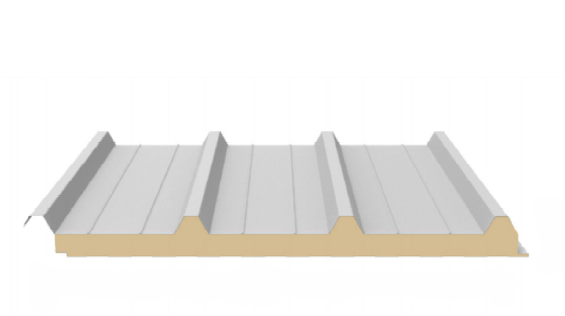

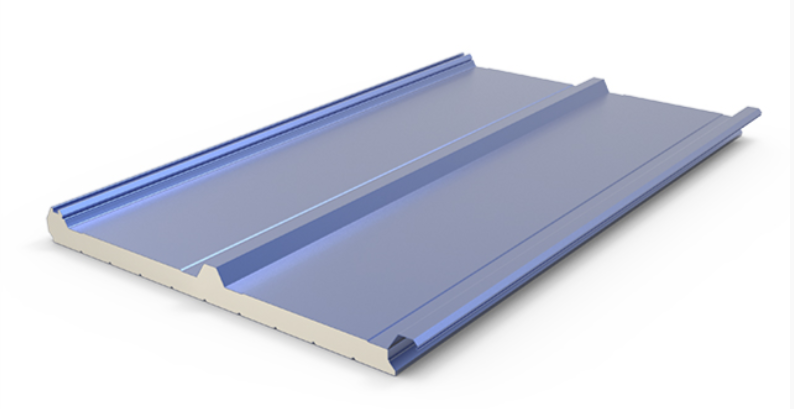

PU sandwich panel

SDpanel PU Panels System comprises of Pre-fabrication sandwich panels with CFC free Polyurethane Foam at a density of 40+/- 2 kg/cu.m as a core and with profiled sheeting / plain ribbed sheeting made out of Galvanized / Galvalume steel as facing on both sides. SDpanel PU Panels come with standard Tongue and Groove Joints for Cold Rooms and Roofing panels and with Concealed fixing system arrangement for Cladding of Buildings.SDpanel PU Panels are available in a standard width of 1m and in various thickness to suit the Industry requirements.

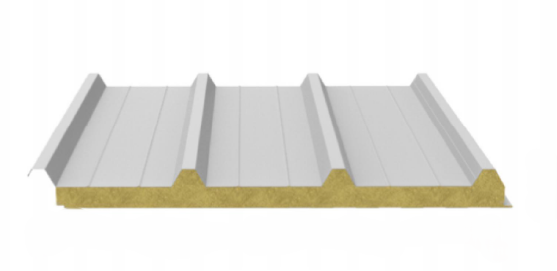

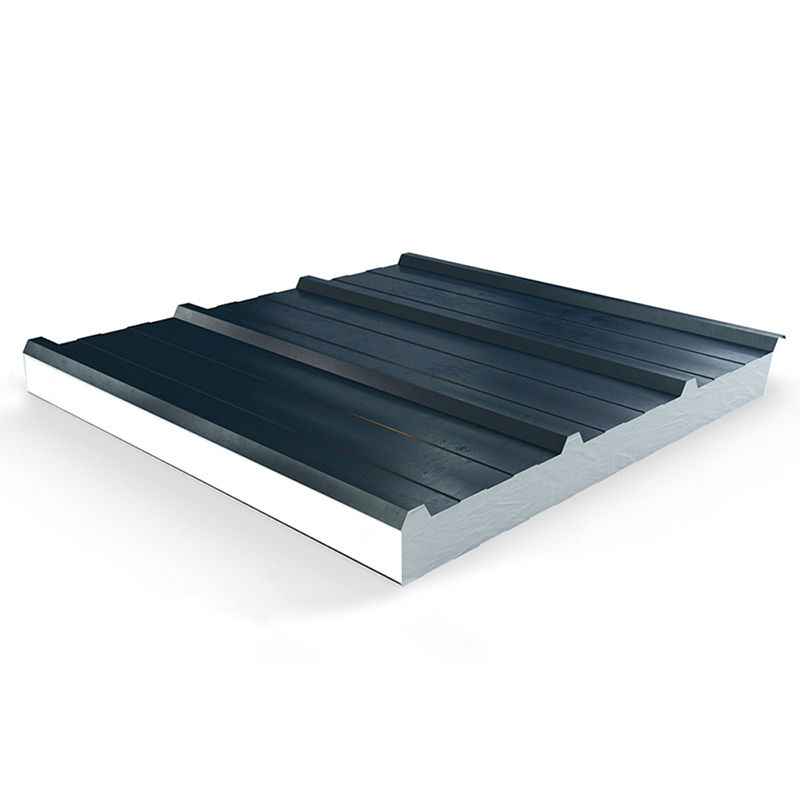

EPS sandwich panel

SDpanel EPS Panels System comprises of Pre-fabrication sandwich panels with Polystyrene (EPS) rigid foam at a density of 12-16 kg/cu.m as a core and with profiled sheeting / plain ribbed sheeting made out of Galvanized / Galvalume steel as facing on both sides. Due to the advantages as heat and sound insulation, high load capacity, EPS panels are applied as external walls and internal division walls, installed vertically or horizontally on single- or multi-span structure.The panels can be installed horizontally or vertically.The installation eliminates the need for additional fasteners.

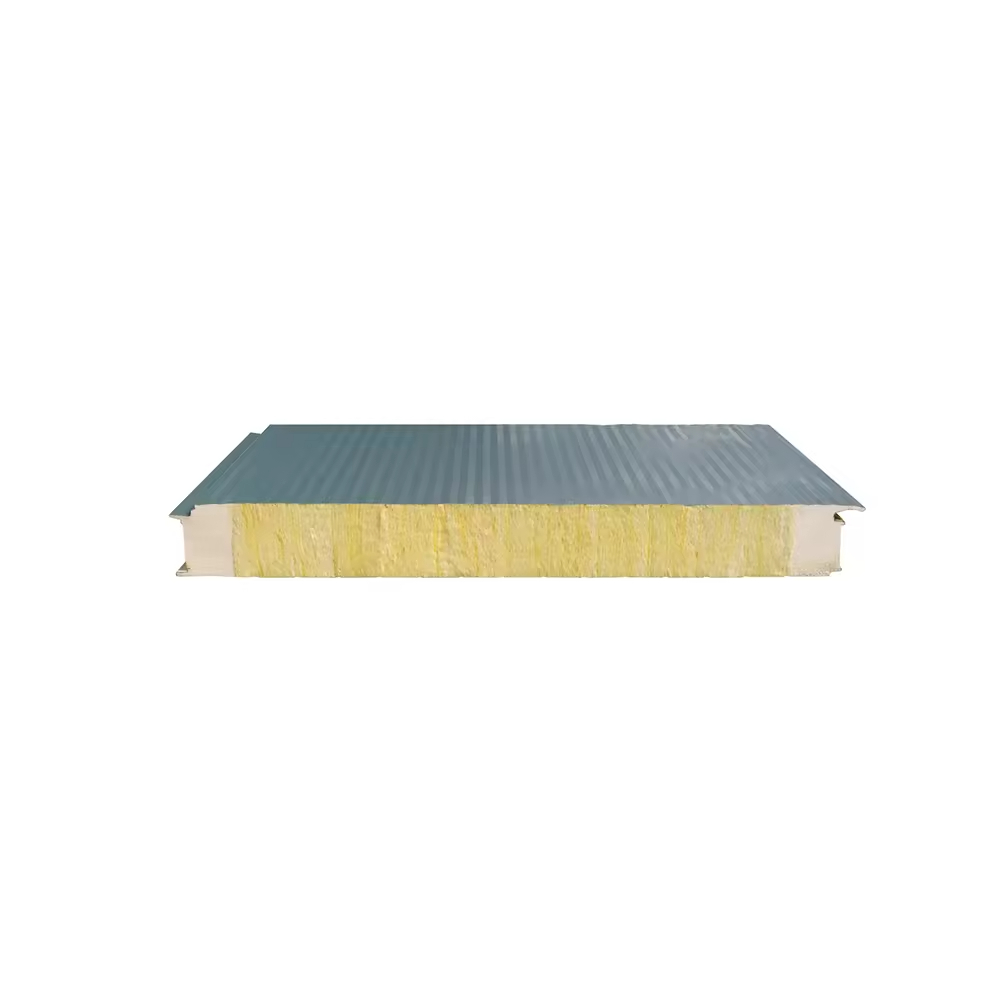

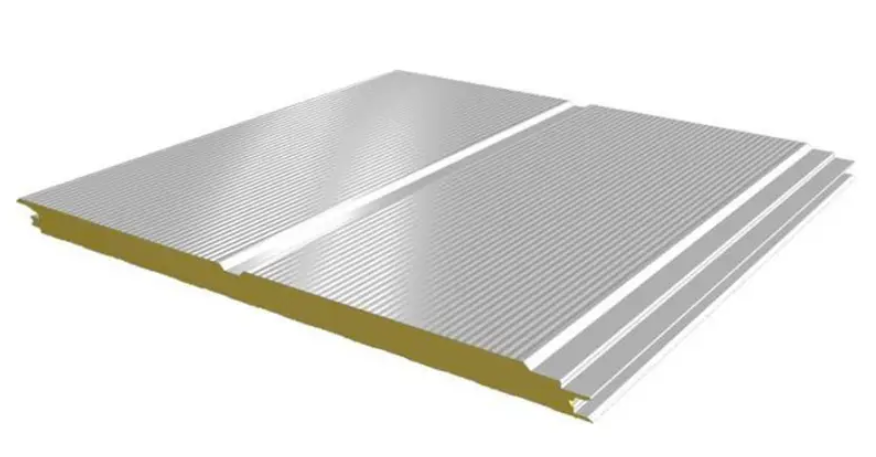

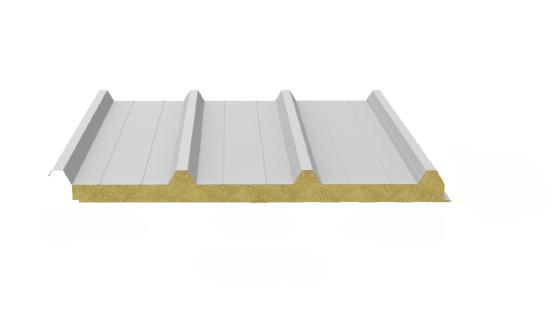

Rock wool sandwich panel

SDpanel Rockwool Panel System comprises of pre-fabricated composite sandwich panels with high density Rockwool converted to Lamellar as core and profiled / plain, colour coated Galvanised Steel / Galvalume steel sheet facing on both sides, complete with joint sealants and fixing ancillaries. SDpanel Rockwool Panels come with concealed fixing system arrangement for cladding of buildings and with profiled sheets for Roofing and cladding applications. SDpanel Rockwool Panles are available in a standard width of 1m and in various thickness to suit the Industry requirements.

Frequently Asked Questions

Rock wool sandwich panels are highly regarded for their fire resistance, making them a preferred choice in fire-sensitive constructions. Rock wool sandwich panels offer robust fire resistance, typically achieving EI30 to EI120+ ratings. Their performance is contingent on design specifics, including core thickness and facing materials, ensuring compliance with global fire safety standards.

The thickness of surface galvalume steel or PPGl steel can range from 0.4 to 0.8 mm ,Aluminum sheet thickness can range from 0.6mm to1.2mmwhile that of the whole sandwich panel will range from 50 to 200 mm.The thicker the Rockwool sandwich panel, the more efficient the insulation.

EPS sandwich panel predominantly comprises of expanded polystyrene. This materialcomprises varieties of identical small molecules that are made of plastic films. lt characterizes ameasure of combustibility. In addition EPS sandwich panel usually added fire retardant.

The use of polyurethane sandwich panels in various industrial and residential applications is very popular. Because it has a thermal conductivity of 0.022 W/Mk, it is able to ensure a constant temperature, whether it is a wall or roof panel or any other part.