Home

Why choose SDpanel

High thermal insulation

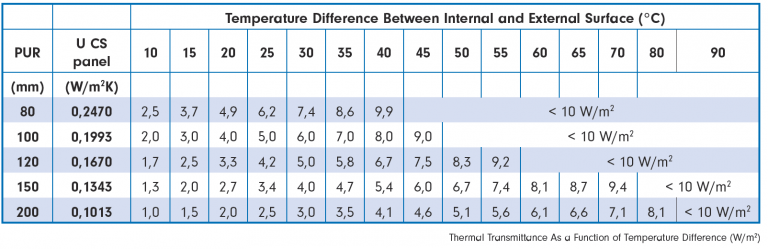

The thermal insulation of the polyurethane sandwich panel is the highest with a density of 40kg/m3

Easy to install

As simple as positioning and screwing the panel to the existing structure. And if you need help, we give you a free manual

Guaranteed quality

All our panels offer maximum quality and durability for decades,and Passed various certifications and tests.

Good fire resistance

The fire resistance of rockwool sandwich panels is the highest on the market, up to Class 1.

Categories

Hot Products

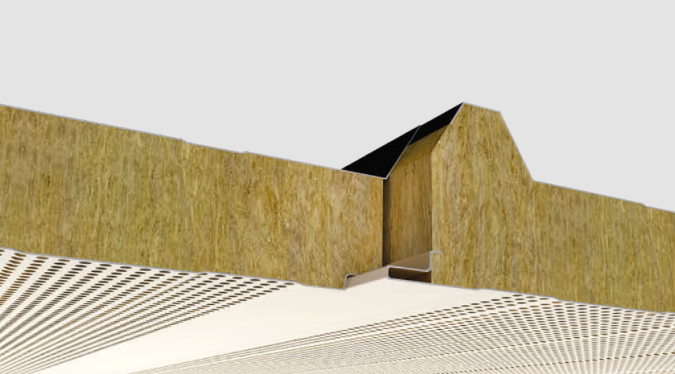

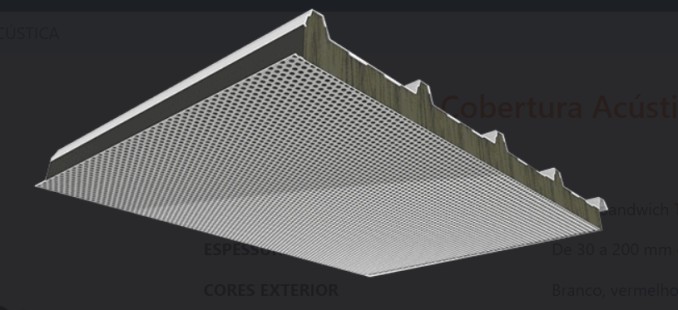

Acoustic sandwich panels

Project Galley

Sandwich Panel Cores

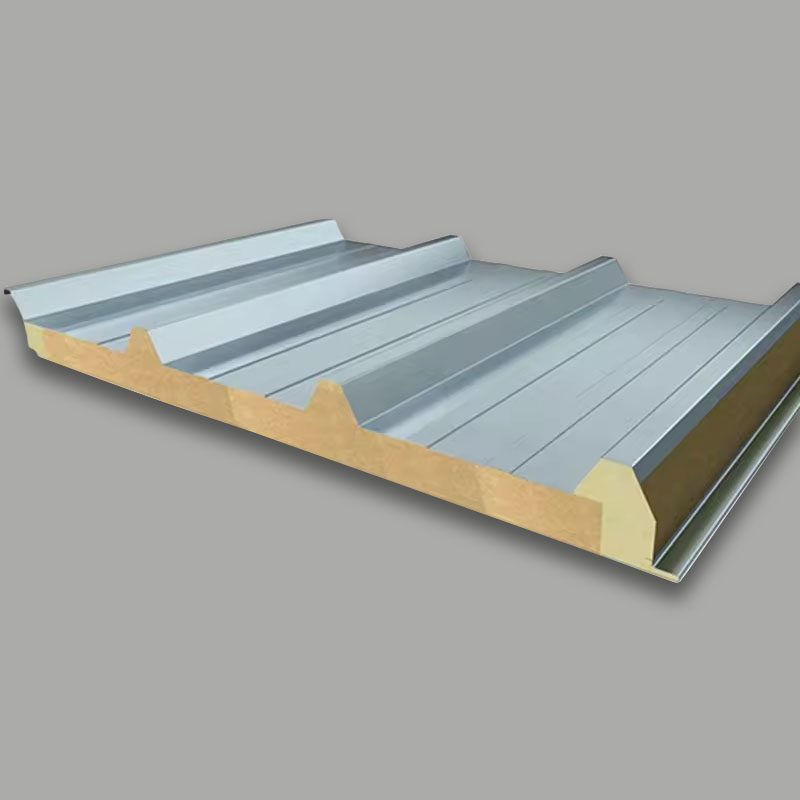

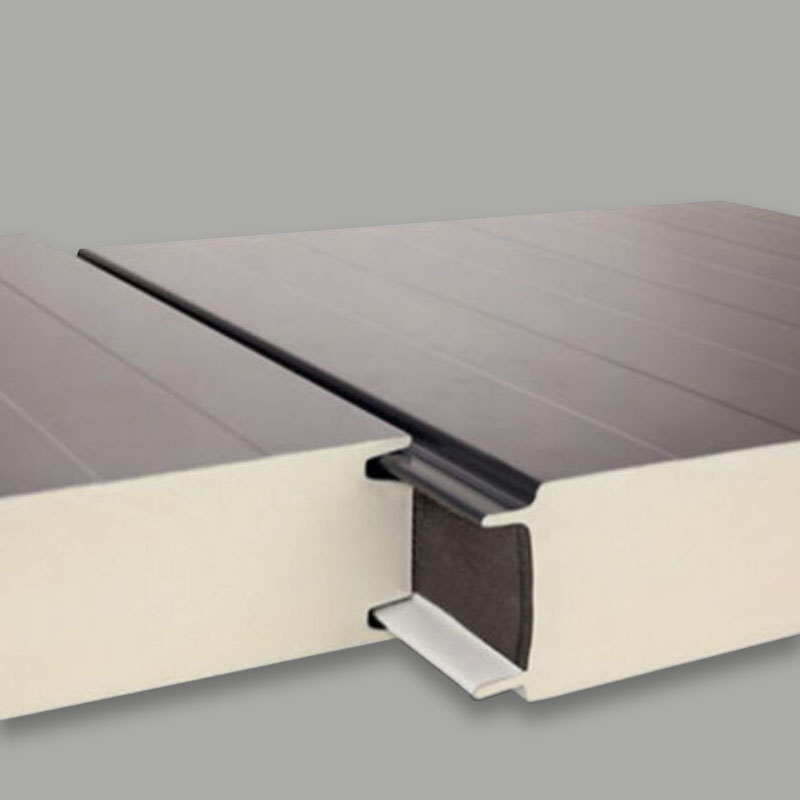

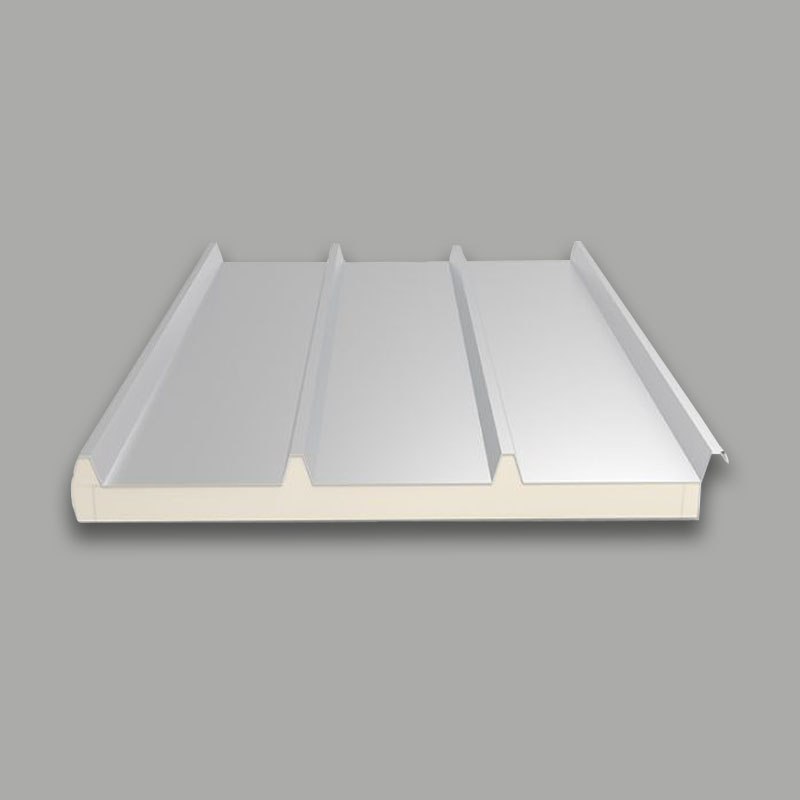

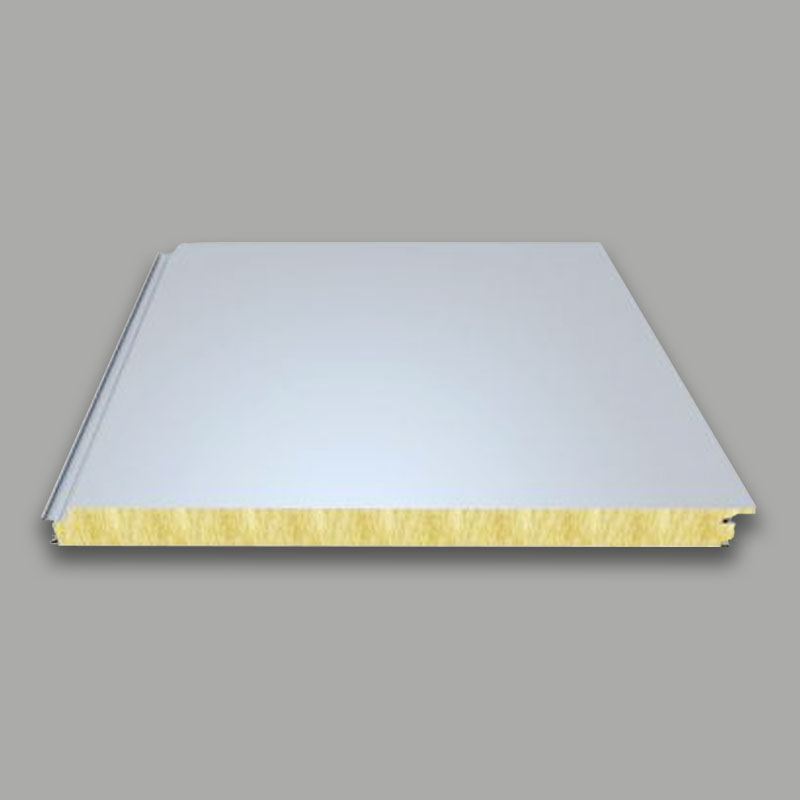

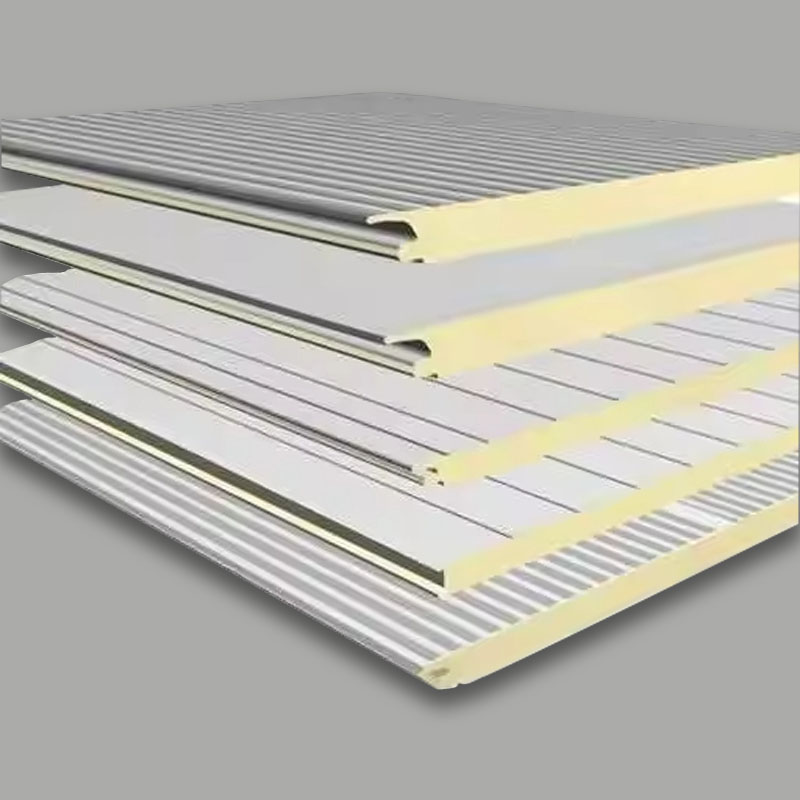

The core of sandwich panels can be:

- made of polystyrene with a density of 12.5 kg/m³ produced by our own production.

- made of rigid polyisocyanurate (PlR) foam with a density of 40 kg/m³ or 35kg/m³(LITE),

- made of mineral wool with a density of 100 kg/m³ and 85 kg/m³ (LITE),

- made of expandable polystyrene(EPS) foam with a density of 12 kg/m³

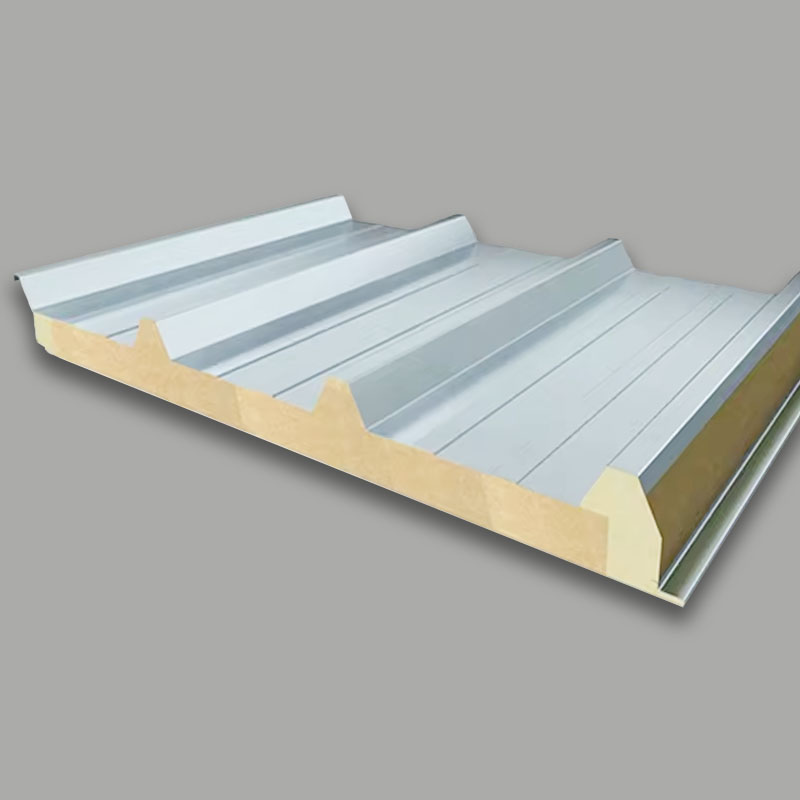

Application of sandwich panels

Sandwich panels are used in construction, among others:

- industrial production and commercial halls,

- warehouses,

- office and service complexes,。 containers,

- agricultural and food industry facilities,

- cold and frosty,

- roofing of objects.

Properties of sandwich panels

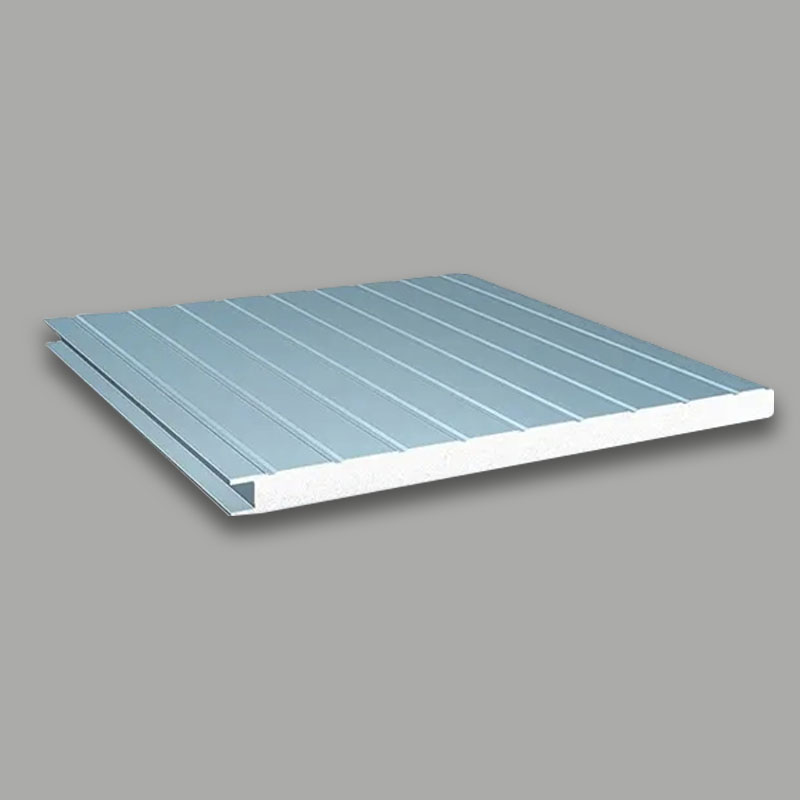

Thickness of sandwich panels:

- Thickness of wall sandwich panels: from 40 mm to 200 mm,

- Thickness of roof sandwich panels: from 40 mm to 200 mm,

Width of sandwich panels:

- Modular width of wall sandwich panels: 500mm–1000 mm

- Modular width of roof sandwich panels: 950,1000 mm

Properties of metal sheet

Material of metal sheet:

- PPGI Sheet,

- Stainless steel,

- Aluminum Alloy

Thickness of metal sheet:

- PPGI Sheet : 0.4mm–0.8mm

- Stainless steel: 0.4mm–0.8mm

- Aluminum Alloy: 0.8mm–1.2mm

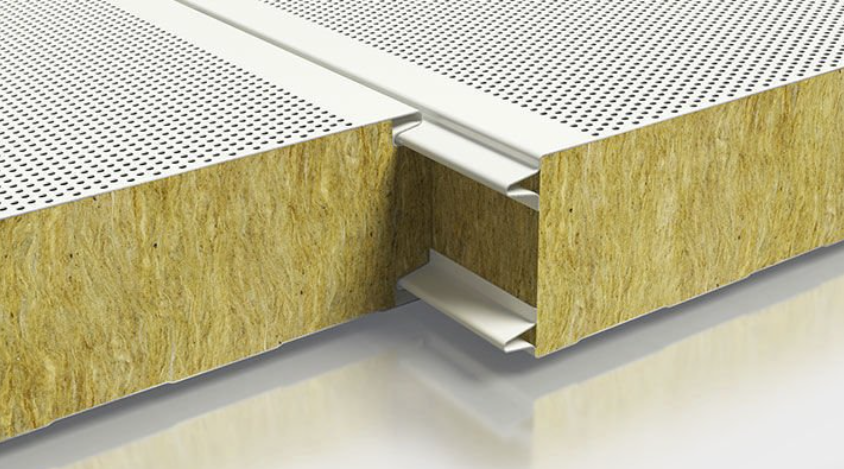

Cleanroom Panel standards

Cleanroom Classes Corresponding to Sandwich Panel Standards:

- ISO 5(Class 100):Stainless steel sheet + rock wool core, seamless welding, conductive coating

- SO 7(Class 10,000):Antibacterial color steel sheet + PU core, airtight rubber strip

- ISO 8(Class 100,000): Aluminum-zinc steel sheet + rock wool core, conventional sealing

Sandwich panel material selection

Material of metal sheet:

- Stainless steel (304/316L): high corrosion resistance, suitable for bio-pharmaceutical, food grade clean room, thickness usually 0.5 ~ 1.2mm.

- Aluminum zinc-plated color steel sheet: the surface needs to be coated with PVDF or antimicrobial coatings, thickness of 0.5 ~ 0.8mm.

- Aluminum-magnesium alloy sheet: lightweight and oxidation resistance, suitable for electronics industry clean room.

Core material selection:

- Rock wool (Class A fireproof): density ≥120kg/m³, suitable for clean rooms with fireproofing requirements (e.g. pharmaceutical factories).

- Polyurethane (PU/PIR): low thermal conductivity (0.022-0.024 W/(m-K)), good heat preservation, but need to meet the B1 fire standards.

- Magnesium glass panel: inorganic material, moisture-proof and mold-proof, suitable for high humidity environment (e.g. laboratory).

Advantages of cold room panels

The advantages of refrigerated panels are:

- Thermal Efficiency: High R-value cores (PUR/PIR) minimize heat transfer.

- Structural Strength: Rigid skins provide durability and load-bearing capacity.

- Lightweight & Easy Installation: Prefabricated panels reduce construction time.

- Hygienic Surfaces: Smooth skins facilitate cleaning, crucial for food safety.

Applications for Cold storage panels

SDpanel’s cold storage panels are typically used in facilities such as food cold rooms, pharmaceutical and medical cold rooms, flower coldstorages, cold chain warehouses, poultry farms, seafood quick-freezefacilities, fruit and vegetable storages, slaughterhouses, meat processingplants, wineries, dairy factories, ice cream companies, beverage plants,quick-freeze tunnels, food processing plants, container cold chain trucks,cold room trailers, and in public areas of hotels, motels, and supermarkets.

Latest from Blog

The freshest and most exciting news